Description

Product Introduction

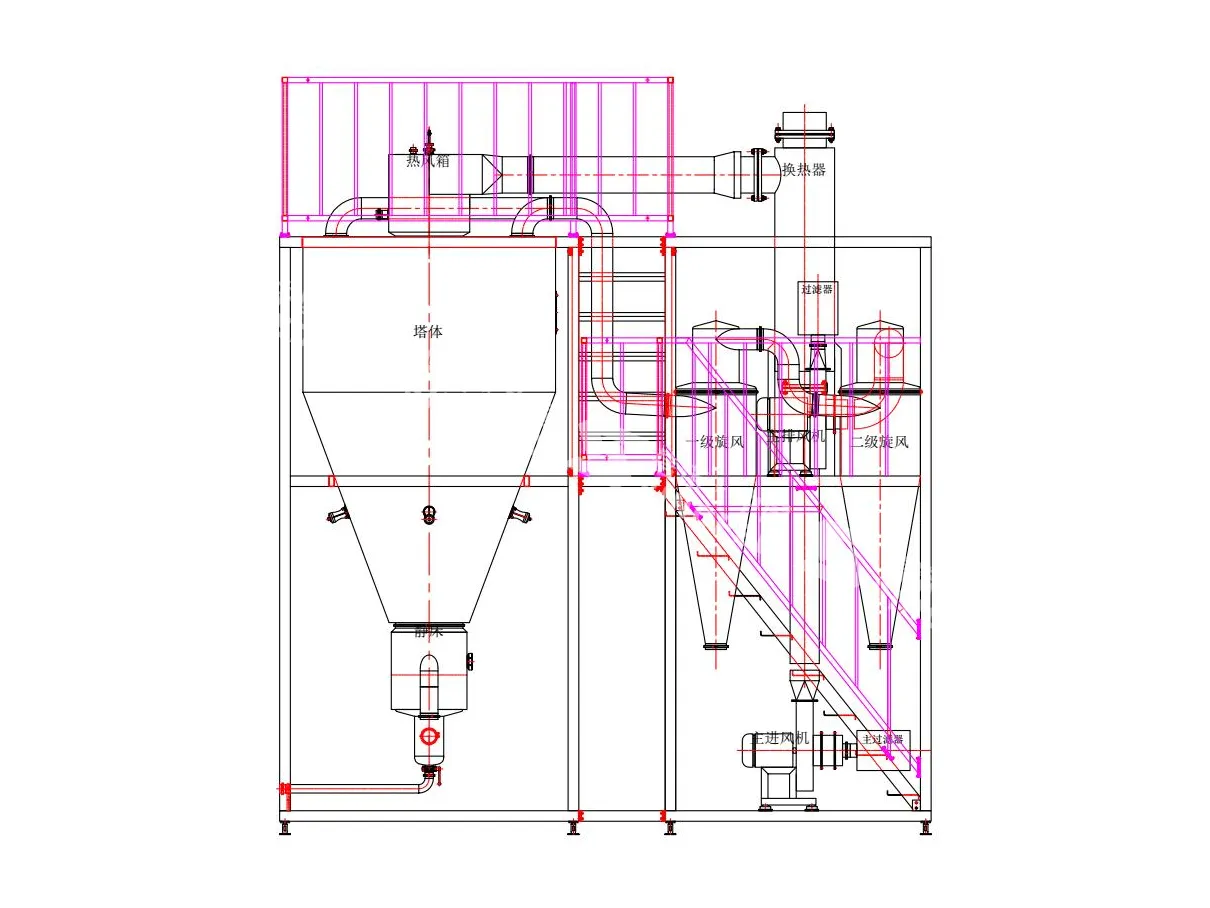

The materials are dried into powder particles with moisture content meeting the requirements, the evaporated water is taken away by the hot air and discharged into the atmosphere by the exhaust fan through a two-stage cyclone separator. The fine powder taken away from the exhaust duct of the tower body is collected once by the primary cyclone separator, and then again by the secondary cyclone separator. The collected powder is collected into the powder receiving bucket, and the waste air is discharged to the atmosphere through the exhaust fan.

Product Parameter

| Water evaporation capacity | 30kg/h, (small) |

| Feed rate (at 50% concentration) | 60kg/h, (depending on the characteristics of different products and the evaporation rate of the concentration) |

| Feed concentration | 20-50% (depending on different products) |

| Inlet air temperature | 160~190 ℃ |

| Exhaust temperature | 80~100 ℃ |

| Temperature inside the tower | 80~100 ℃ |

| Installed capacity | 133.74kw, (small) |

Main Features

- Air intake system

(1) The intake air filtration system adopts a sub high efficiency filter.

(2) The air inlet heating system adopts the method of electric heating.

(3) The air intake unit is modular, making it easy to disassemble and clean all components.

(4) The temperature of the hot air inlet can be adjusted within the range of 160~190 ℃.

- Exhaust system

(1) The method of two-stage cyclone separation is used for powder capture. Cyclone separation is a commonly used gas solid separation method, and the waste air is converted into clean air for discharge.

(2) The exhaust outlet temperature is adjustable within the range of 80 to 100 ℃.

- Spray system

The material is quickly atomized and sprayed into the tower through a spray gun and nozzle.

(1) High pressure pump and volute type M-type nozzle are used for atomization in the production of sticky materials and products requiring high bulk density and fine particles.

(2) When producing non viscous materials and products requiring low bulk density and large particles, peristaltic pumps, two fluid nozzles for atomization, and secondary polycondensation are used.

- Drying system

(1) The inner wall of the tower maintains a 2B plate surface, and the welds are polished to reduce fine powder adhesion on the tower wall.

(2) The angle of the cone portion of the equipment is appropriately reduced, thereby accelerating the flow of materials on the cone.

(3) The equipment is equipped with a quick opening cleaning interface and a sewage outlet, which is convenient for cleaning.

(4) Each section of the equipment is equipped with an anti-static device, which can guide the static electricity generated by materials into the ground in a timely manner, protecting the equipment and operators.

(5) The inner wall of the drying tower is made of 2mm stainless steel plates, which can withstand a negative pressure of 4000Pa and will not be damaged in the event of incorrect operation. The outer wall is made of 1mm stainless steel plate.

- Control system

The control system adopts a touch screen + PLC, with a high degree of automation, which can store data, and parameters such as temperature and pressure can be digitally displayed, with an overtemperature alarm.

Working Principle

1.This machine adopts a new type of air flow structure with upward air intake, which greatly protects the protein, improves the freshness of the product, and reduces the denatured protein of the product.

- The spiral wind sweeps the tower wall, resulting in less powder accumulation inside the tower.

- The hot air box has a new type of air distribution structure, which requires no adjustment to ensure uniform air intake.

- The tower top is equipped with a cold air coil to avoid the problem of coke powder on the tower top.

- The tower wall is equipped with an air hammer controlled by a pulse controller and a related compressed air system.

- The operating pressure can be adjusted within 1-3 bar, and the tapping frequency can be adjusted.

- The tower wall is automatically cycled to avoid powder accumulation on the tower wall. The operation adopts automatic control, equipped with frequency converter, temperature sensor, PLC program control, and a set of manual control buttons, which is simple to operate and easy to control.

Features Application

Widely used in other food industry powder production, such as coffee powder, cocoa powder, protein powder and so on. Through the drying tower, liquid raw materials can be quickly and efficiently converted into solid powders, retaining the taste and nutrients of raw materials while extending their shelf life.

Reviews

There are no reviews yet.